Paper edge protector / edge board production line is made of 10 parts: paper stand→gluing part→composite part→guiding part→preforming part→heating part→forming

Paper edge protector / edge board production line is made of 10 parts: paper stand→gluing part→composite part→guiding part→preforming part→heating part→forming

Contact Us

| Model | SANPPL-120G |

| L protector size | 25-100mm (can be symmetrical and asymmetrical) |

| Thickness | 2-10mm |

| Applicable inner paper | 360-600gsm bobbin fiber paper |

| Applicable surface paper | 175-250gsm kraft paper |

| Core diameter of paper roll | 3” (76mm) (4” or other size possible) |

| Max. quantity of Layer | 13 layers, including one layer surface paper |

| Working speed | 0-50m/min |

| Control system | PLC, servo motor, touch screen (HMI) with automatic alarm and failure notice, easy for operation and adjustment. |

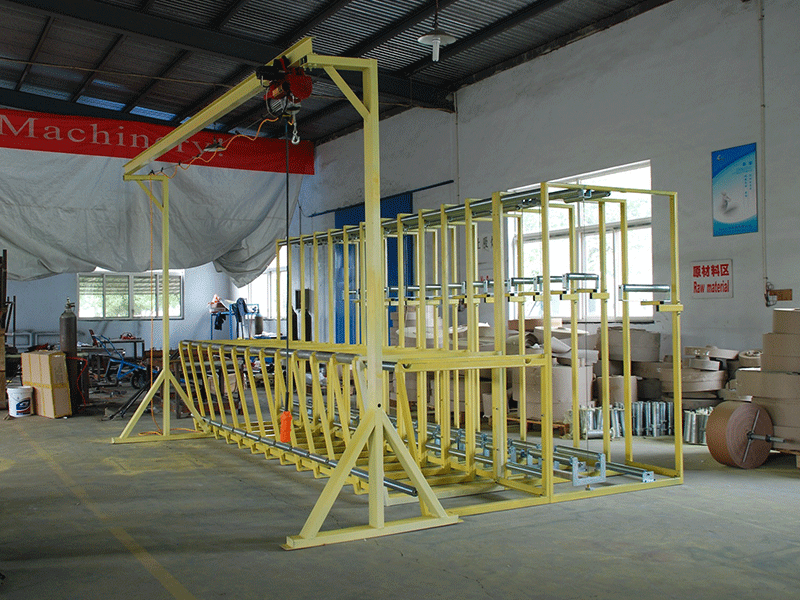

| Paper stands | Model G. Suspended paper stands (buffering effect) with hoist for inner paper. Possible to load 13 reels. |

| Forming wheels | Chamber hanging type, easy to change molds |

| Method to load paper roll | Load inner paper rolls by hoist (along with machine). No need to stop machine when loading paper rolls. |

| Applicable paper roll diameter | Max.1300mm |

| Paper feeding and compounding | Model G, step type with complex structure |

| Gluing system | Cascade type gluing system |

| Glue feeding | Automatic feeding by diaphragm pump |

| Pressing adjustment | Pneumatic pressing to protect paper and easier operation |

| Cutting method | Hydraulic cutting |

| Moving of cutting head | Servo motor controlled by PLC |

| Min. cutting length | 100mm |

| Max. cutting frequency | 90times/minute |

| Cutting tolerance | 1000±0.2mm |

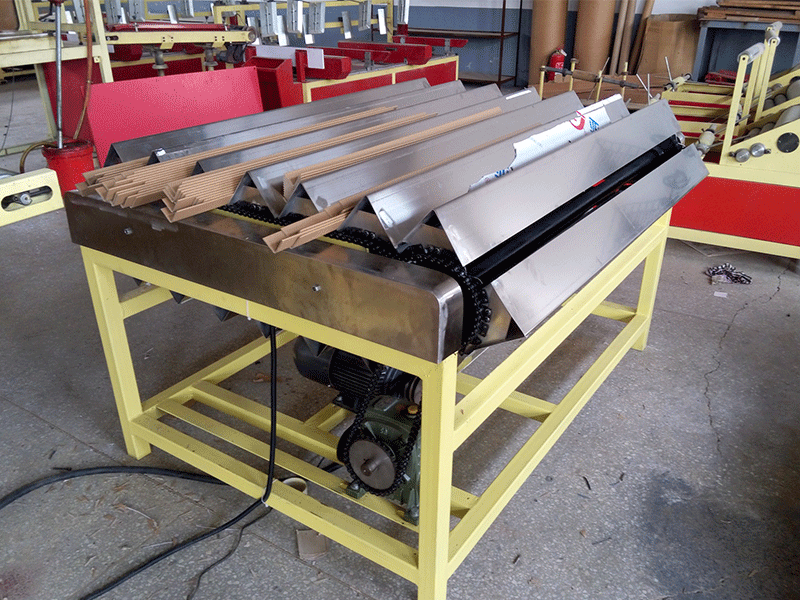

| Stacker | Model G, automatic stacking |

| Motor for forming section | two motors with inverter, with high power, direct connected reducing motor |

| Power supply | 20.7KW 220V, 60HZ 3 phase |

| Air supply | 0.6Mpa, 0.2m3/min |

| Total weight | 4.5T |

| Dimension | 24.5×1.8×1.9m (highest point for hoist is 2.9m) |

| Required container | One 40’ container |

PLC control

Automatic feeding, stacking system. Low intensity working strength with high efficiency.

Pneumatic pressure system. The pneumatic pressure device is flexibility, so it is safe and reliable, paper production is high quality.

Glue temperature control device. Electrical heating system, ensure the quality of the production, especial in low temperature working.

High speed at 50m/min, save time and labor to save cost.

Suspended paper stand with buffering effect, replace the paper rolls with hoist, no need to stop the machine. Applicable inner paper: 360-600gsm bobbin fiber paper or corrugated medium paper or testliner. Paper less the 360gsm can be used but paper quality should be good. Must have no breaking during production.

Automatic controller for glue temperature. With diaphragm pump and heating. Feeding glue by diaphragm pump and applying glue by pipes. Suitable for single face gluing and double faces gluing. Heating temperature is 38-40℃. Heating glue is normally used in winter. To make glue dry easier and keep same high speed as in other seasons. When the adhesive is heated it dries faster.

Hydraulic cutting system, maximum frequency is 90 times/minute.

Automatic stacking system with counter, no need to count manually. After production, the edge boards can be transported and handled. No need to spend special time drying them. They will be dry in 2-3 days.

Product Inquiry

2025/04/22

2025/04/22

2025/04/15

2025/04/15

2025/04/08

2025/04/08

2025/02/25

2025/02/25